A successful drydock is rarely defined by what happens in the yard. It is defined by what does not go wrong after the vessel relaunches.

Picture this. The drydock wraps up on schedule. The vessel is back in service. Everything looks good. Until weeks or months later, a small leak appears. Then a compliance issue. Then a system failure that forces the vessel back out of operation.

What felt like a successful drydock quickly turns into unplanned downtime.

In many cases, the root cause is not poor workmanship. It is critical flow components that were left in place because they looked acceptable at the time or were difficult to access once the schedule tightened.

This checklist is designed to help shipowners, operators, and shipyard teams focus on the flow components that deserve attention while access is available, so relaunch is smooth, compliant, and predictable.

Flow systems work quietly until they do not. During drydock, access to piping systems, tanks, and machinery spaces creates a rare opportunity to address components that are difficult or costly to service while afloat.

Common post relaunch issues often trace back to components that were left in place because they looked acceptable at first glance or were deferred to save time.

The reality is simple. If it is aging, difficult to access, or critical to system integrity, drydock is the moment to act.

Use this checklist as a starting point when planning inspections and replacements.

Valves regulate flow, pressure, and safety across nearly every onboard system. During drydock, valves should be evaluated for both mechanical condition and operational performance.

Real world issue:

A vessel completes drydock on time but experiences uneven flow and pressure imbalance once back in service. Investigation reveals aging manual valves that no longer regulate flow properly. Retrofitting at sea leads to downtime that could have been avoided during drydock.

Best practice solution:

Replacing aging valves during drydock improves reliability and long-term system control. Wouter Witzel butterfly valves are a popular onboard choice thanks to their tight shutoff, smooth operation, and five-year manufacturer warranty.

For improved efficiency, smart balancing and control solutions such as Frese valves automatically regulate flow, reduce energy loss, and minimize post relaunch adjustments, delivering cost savings.

Vent heads are often overlooked because they sit quietly until they fail. However, improper ventilation can create serious safety and compliance risks.

Real world issue:

After relaunch, a vessel experiences repeated tank alarms and moisture contamination. The cause is traced back to corroded vent heads that allowed water ingress during heavy seas.

Best practice solution:

Installing high quality vent heads such as Winteb, helps protect tanks from water ingress while maintaining proper airflow and compliance. Designed for harsh maritime environments, Winteb vent heads offer superior corrosion resistance and a compact profile that delivers high airflow performance while reducing structural load and improving installation flexibility during refits.

Pipe couplings are used to join pipe sections while allowing for limited movement, vibration, and thermal expansion in operating systems. Over time, wear and fatigue can reduce their ability to maintain a secure, leak free connection.

Real world issue:

A pipe coupling fails weeks after relaunch due to vibration and alignment stress. Repairing the connection requires hot work and a system shutdown while the vessel is in service.

Best practice solution:

Mechanical pipe couplings such as Youngnam couplings provide a secure, flexible connection without welding, allowing systems to accommodate movement while reducing installation time and hot work risks.

Press and mechanical pipe fittings create permanent, leak free connections in critical onboard piping systems. While small in size, failures at these connection points can shut down entire systems.

Real world issue:

A fitting begins leaking shortly after relaunch. Access is restricted, repairs are disruptive, and temporary fixes become long term operational headaches.

Best practice solution:

Press fitting systems such as RM press fittings provide secure, flame free connections that reduce installation time, eliminate hot work risks, and create consistent, reliable joints during drydock.

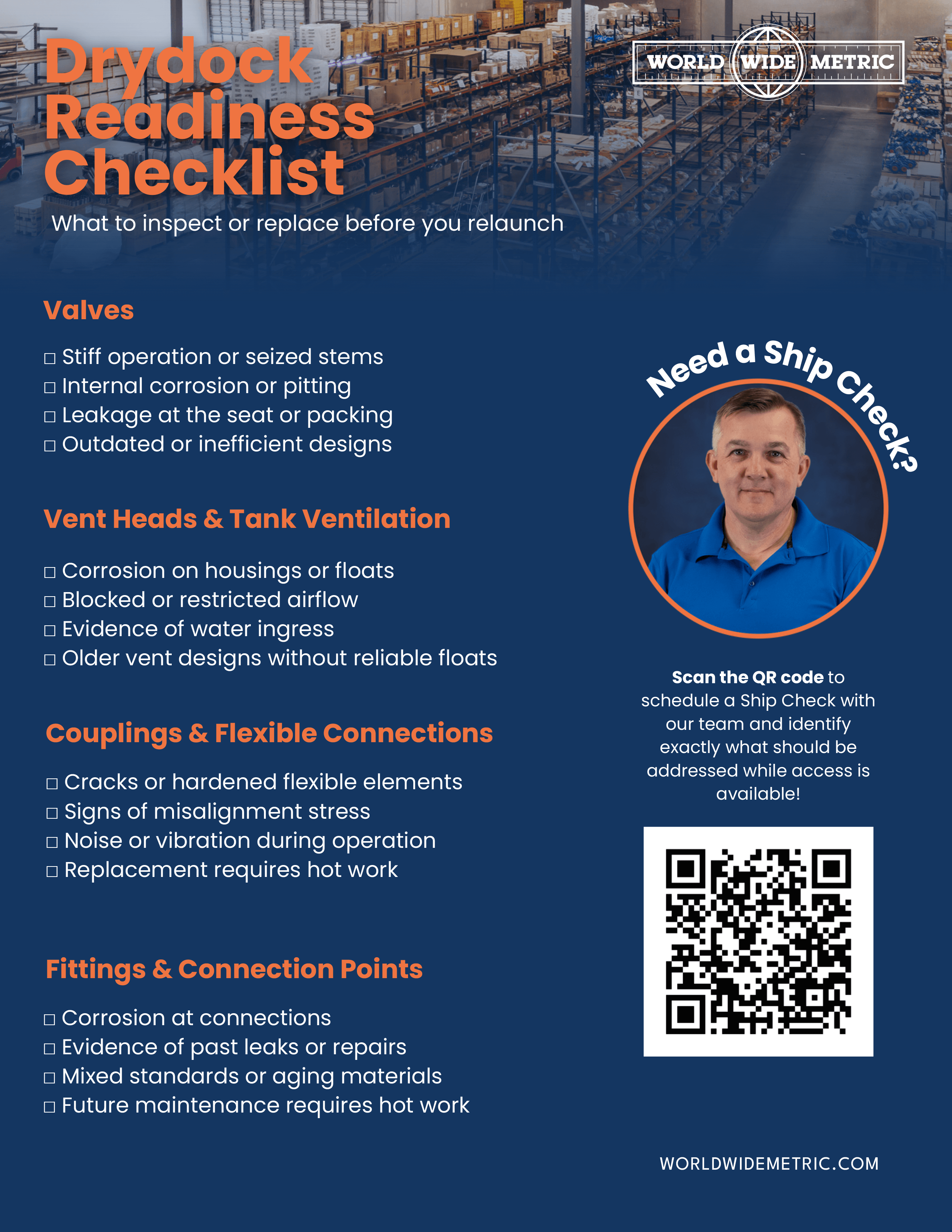

Ship Checks are designed to solve this problem before it starts.

This consultative service takes place ahead of drydock and focuses on identifying exactly which valves, vent heads, couplings, and fittings should be addressed while access is available.

Instead of reacting to issues during drydock, Ship Checks allow teams to plan proactively and execute with confidence.

Drydock success is not just about what gets done. It is about what does not have to be revisited after the vessel is back in service.

By addressing critical flow components upfront and leveraging expert guidance before the dock date, shipowners and operators can avoid costly surprises and keep operations moving forward.

Download our Drydock Readiness Checklist for a quick reference tool to support planning and inspections.

Download the Checklist

If questions come up as you prepare for drydock, our team is available to help. Request a Ship Check or pre drydock consultation to evaluate critical components. World Wide Metric is here to help you plan smarter, source confidently, and relaunch without regrets.

Email Us